In the world of precision engineering, ball bearings serve as the fundamental heartbeat of rotational motion. As industrial machinery evolves toward higher speeds and more extreme environments, selecting the right bearing becomes a critical factor in operational efficiency and system longevity. This comprehensive guide explores the structural intricacies, material sciences, and specialized applications that define ZGBK®'s approach to high-performance bearing solutions.

Explore the technical sections below to master the essentials of modern bearing technology.

Table of Contents

- 1. Introduction

- 2. Definition of Ball Bearings

- 3. Function of Ball Bearings

- 4. Common Applications of Ball Bearings

- 5. Types of Ball Bearings

- 6. Materials Used in Ball Bearings

- 7. Installation and Maintenance of Ball Bearings

- 8. Future Trends in Ball Bearing Technology

- 9. Conclusion

- 10. Types of Ball Bearings Table

Introduction

Ball bearings are mechanical components designed to reduce friction between moving parts in machinery. They consist of a series of spherical balls that are placed between two or more rings, known as races, allowing for smooth rotational or linear motion. This design significantly minimizes the resistance that occurs when parts move against each other, which is crucial for enhancing the overall efficiency of industrial machinery.

The primary function of ball bearings is to support loads while enabling free movement, which is vital in various applications where precision and reliability are paramount. These components are found in numerous types of industrial machinery, including motors, generators, conveyors, and pumps. By allowing parts to rotate with minimal friction, ball bearings also help in prolonging equipment lifespan and reducing maintenance needs, thus saving time and resources for businesses.

Furthermore, the importance of ball bearings extends beyond mere friction reduction; they play a critical role in the performance and safety of machines. In applications such as aerospace, automotive, and manufacturing, the reliable function of ball bearings is essential, as their failure can lead to significant operational disruptions and increased safety risks. Maintaining the proper functioning of these components ensures smoother operations, greater productivity, and enhanced performance.

In this blog post, we will delve deeper into the characteristics, types, and applications of ball bearings. Understanding these components will provide insights into their design, functionality, and the myriad of ways they contribute to the efficient operation of industrial machinery.

Definition of Ball Bearings

Ball bearings are integral mechanical components in numerous industrial applications, facilitating smooth rotation or linear movement by reducing friction between moving parts. Essentially, a ball bearing comprises an outer ring, an inner ring, a series of balls, and a cage, also referred to as a separator, which maintains the appropriate distance between the balls. The main function of a ball bearing is to support loads while minimizing the friction produced between surfaces, thereby improving the efficiency and longevity of machinery.

Within the broader category of bearings, which includes roller bearings and sleeve bearings, ball bearings are distinguished by their spherical rolling elements. This design allows them to handle both radial and axial loads, providing versatility in a wide range of applications from electric motors to automotive systems. The presence of the small spherical balls enables them to rotate freely, resulting in decreased contact area and subsequently lower resistance during motion.

The operational mechanics of ball bearings involve the rotation of the inner ring around the outer ring, with the balls acting as a mediator that separates the two surfaces. As the inner ring spins, the balls roll along the raceways of both rings, resulting in a smooth and efficient transition of motion. The selection of proper lubrication is essential in maintaining the ball bearing’s performance, as it aids in further reducing friction and wear. Regular maintenance checks can enhance their lifespan and efficiency in machinery.

Function of Ball Bearings

Ball bearings play a critical role in the functionality of industrial machinery by facilitating smooth rotational or linear movement. Their primary function is to reduce friction between moving parts, which, in turn, enhances the overall efficiency and performance of machines. By allowing for easier movement, ball bearings help to minimize wear and tear on components, which can lead to increased operational lifespan and reliability.

For instance, consider the common application of ball bearings in electric motors. In these motors, ball bearings support the shaft and enable it to rotate freely. This seamless rotation is crucial for maintaining the performance of the motor and ensuring that it operates at peak efficiency. Similarly, in bicycles, the ball bearings in the wheels and pedals allow for smooth pedaling and effortless movement, significantly improving the riding experience.

Moreover, ball bearings contribute to the durability of machinery by dissipating heat generated during operation. By minimizing direct contact between metal surfaces, they help maintain a lower operating temperature, which is essential in preventing damage due to overheating. In high-speed applications, such as in jet engines or turbine systems, the reliance on high-quality ball bearings ensures that performance remains uninterrupted and the machinery continues to run optimally.

In summary, the function of ball bearings extends beyond mere movement facilitation; they are vital to reducing friction, wear, and heat generation. Whether in everyday devices like appliances, bicycles, or complex industrial equipment, their performance directly impacts the effectiveness and longevity of machinery. Recognizing their role can help in appreciating the intricacies of industrial applications where even the smallest components like ball bearings are pivotal to overall performance.

One of the most critical metrics for evaluating a ball bearing’s performance is its service life, often measured as L10 Life. Understanding how long a bearing will last under specific loads is essential for preventing machine downtime. For a precise estimation, you can use our Online Bearing Life Calculator.

Common Applications of Ball Bearings

Ball bearings are fundamental components utilized in various sectors, providing support and reducing friction in moving parts of machinery. Their application extends across several industries, prominently in manufacturing, automotive, and aerospace. In manufacturing, ball bearings are critical for ensuring efficiency in processes such as assembly lines and conveyors, where they facilitate the smooth movement of heavy machinery. For instance, in conveyor systems, ball bearings support rollers, allowing materials to be transported effortlessly across production lines.

In the automotive industry, ball bearings play a vital role in various vehicle components. They are extensively used in electric motors, where they contribute to the operational efficiency and longevity of the motor’s performance. Additionally, ball bearings are integral in gearboxes, assisting in the smooth transmission of power from the engine to the wheels, thus enhancing vehicle reliability and performance. The precision and durability of ball bearings ensure optimal functionality, thereby impacting the overall safety and efficiency of the vehicle.

The aerospace sector also depends heavily on ball bearings, where they are essential in ensuring the performance of critical applications such as engines and landing gear systems. In aircraft engines, they provide support for rotating shafts and components, reducing wear and ensuring longevity under extreme operating conditions. Moreover, in landing gear mechanisms, the use of high-quality ball bearings is paramount to ensure pilots can safely deploy and retract gear during critical phases of flight.

Overall, the diverse applications of ball bearings across different industries underscore their significance in enhancing the performance and reliability of industrial machinery. Whether it’s in manufacturing, automotive, or aerospace, ball bearings are indispensable in ensuring efficiency and smooth operation.

Types of Ball Bearings

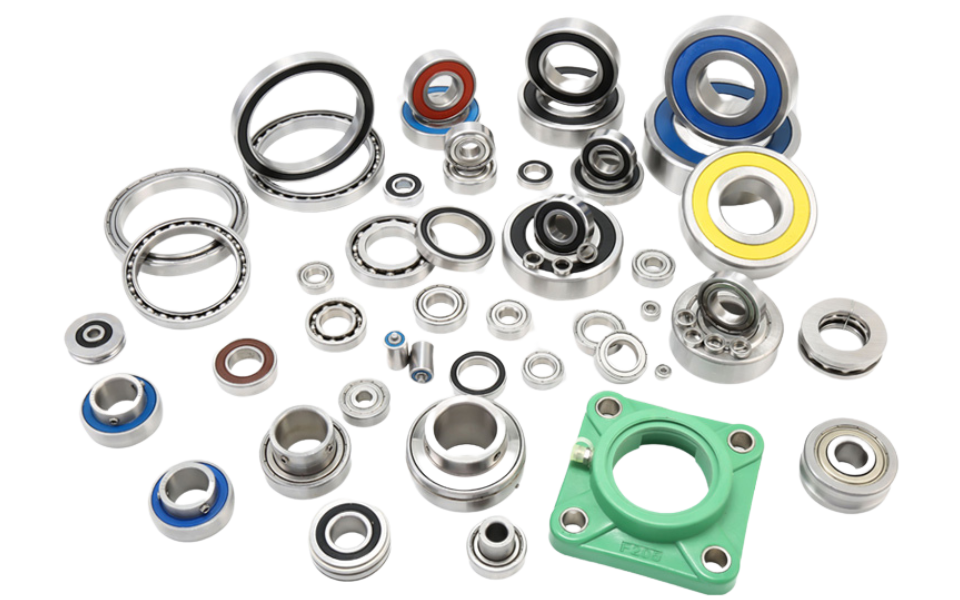

Ball bearings are integral to the efficient functioning of various industrial machines, and understanding the different types available is crucial for selecting the right bearing for specific applications. Each type of ball bearing is designed with unique characteristics that cater to varying operational demands.

One of the most commonly used types is the deep groove ball bearing. This bearing features a simple design that allows it to accommodate both radial and axial loads, making it versatile for numerous applications, including motors, automotive components, and general machinery. The deep grooves enable the bearing to maintain high speeds and operate under moderate to heavy loads, which is why they are favored in many industrial settings.

Angular contact ball bearings, on the other hand, are designed to support axial loads in one direction and are capable of handling higher speeds than deep groove bearings. The key characteristic of angular contact bearings is their ability to withstand combined loads, making them ideal for applications such as high-speed spindles and gearboxes. Additionally, these bearings typically come in pairs or sets to carry loads more effectively.

Self-aligning ball bearings offer a distinct advantage in applications where shaft misalignment might occur. These bearings contain two rows of balls and a common spherical raceway, enabling them to self-align and accommodate slight misalignments or shaft deflections without compromising their performance. They are often used in applications like electric motors and woodworking machines, where such issues are prevalent.

In summary, selecting the appropriate type of ball bearing involves considering the specific operational demands such as load direction, speed, and alignment capabilities. By understanding the unique features and advantages of deep groove, angular contact, and self-aligning ball bearings, users can make informed decisions that optimize performance in their machinery.

Materials Used in Ball Bearings

Ball bearings are crucial components in various machinery applications, and the materials used to manufacture them significantly influence their performance, durability, cost, and suitability for specific applications. The most common materials utilized in the production of ball bearings include steel, ceramics, and plastics, each providing unique advantages and limitations.

Steel is the traditional choice for ball bearings, often selected for its strength and load-bearing capabilities. High-carbon chrome steel, known for its hardness and resistance to wear, is particularly favored in industrial applications. However, steel bearings are susceptible to rust and corrosion, necessitating the use of coatings or lubrication in hostile environments. As a result, steel ball bearings are best suited for applications demanding high strength and where environmental conditions are controlled.

Ceramic materials, such as silicon nitride or alumina, are becoming increasingly popular across various industries. Ceramic ball bearings offer superior hardness, lower density, and enhanced resistance to high temperatures, making them ideal for high-speed applications and environments where steel bearings might fail. Additionally, ceramic bearings are non-magnetic and resist corrosion, providing an advantage in specialized applications like aerospace and semiconductor manufacturing. However, the higher cost of ceramic bearings compared to steel can be a limiting factor for budget-conscious projects.

Lastly, plastic ball bearings, often composed of materials like polyamide or acetal, provide an excellent alternative for low-load applications. These lightweight bearings are resistant to corrosion and are quieter in operation, making them suitable for consumer products, medical devices, and some automotive applications. Plastic’s lower cost, however, comes with limitations in load capacity and temperature resistance, requiring careful consideration based on the application at hand.

Installation and Maintenance of Ball Bearings

Proper installation and maintenance of ball bearings are vital for ensuring their longevity and optimal performance in industrial machinery. When installing ball bearings, it is essential to follow specific best practices to minimize the risk of premature failure. Firstly, ensure that the workspace is clean and free from contaminants, as dirt and debris can interfere with bearing functionality. Prior to installation, inspect the bearing and the housing for any damage or imperfections, as these can adversely affect performance.

Use appropriate tools to handle the bearings during installation; a bearing installer or a soft hammer can help fit the bearing into its housing without causing any surface damage. Additionally, it is important to respect the bearing’s orientation and mounting instructions provided by the manufacturer. Achieving the correct fit within the housing is crucial, as it influences overall bearing operation.

Maintenance schedules should be established, taking into account the operating conditions and environments where the machinery is used. Regular inspections should include checking the bearing for signs of wear, noise, or overheating, which might indicate underlying issues. Environmental factors, such as exposure to moisture or corrosive substances, can also necessitate a more frequent maintenance schedule for ball bearings.

Lubrication plays a crucial role in the life span and efficiency of ball bearings. Selecting the proper lubricant, whether grease or oil, based on the operating speed and temperature is critical. Greases are often favored in applications requiring protection from contaminants, while oils might be more suitable for high-speed applications. Always consult the manufacturer’s specifications when determining the appropriate lubricant types and intervals for reapplication.

Cleaning ball bearings is another essential maintenance practice. When performing maintenance, if cleaning is necessary, ensure that a suitable solvent is used that will not damage the bearings or adversely affect the lubricant. Avoid aggressive cleaning methods, as they can lead to surface damage or contamination. With proper installation and regular maintenance, ball bearings can perform at optimal levels, contributing significantly to the efficiency of industrial machinery.

Regular maintenance aims to reach the bearing’s theoretical L10h life. When a bearing fails prematurely, it’s often due to factors not accounted for in the initial bearing life calculation

Future Trends in Ball Bearing Technology

The advancement of ball bearing technology is increasingly influenced by innovations in material science and precision engineering. As industries strive for improved performance, manufacturers are exploring new materials that enhance durability and reduce friction. High-performance ceramics, such as silicon nitride, are becoming prominent due to their lightweight properties and exceptional wear resistance. These advanced materials can operate under extreme conditions, which significantly extends the lifespan of ball bearings in various applications, from automotive to aerospace.

Furthermore, the integration of lubrication technologies has undergone significant enhancements. Advanced lubrication systems are being developed to minimize energy loss and promote smoother operation. For instance, the introduction of nanotechnology in lubricants allows for better wear protection and reduced viscosity, ultimately leading to improved efficiency in machinery. This development not only eases installation but also lowers maintenance costs by extending the intervals between necessary servicing.

Precision engineering is another critical area that is seeing rapid evolution. The introduction of computer-aided design (CAD) and advanced simulation techniques allows for the meticulous design of ball bearings that are tailored to specific applications. These tools enable engineers to optimize the geometry of bearings, resulting in lower friction coefficients and better load distribution. Consequently, this enhancement leads to more efficient performance and reduced energy consumption, addressing the growing demand for sustainability in industrial practices.

As these trends continue to evolve, the future of ball bearings looks promising. Manufacturers are not only focused on meeting current demands but are also anticipating the future needs of industries, paving the way for innovations that can contribute to the efficiency and longevity of machinery. By embracing cutting-edge technologies in materials and design, the next generation of ball bearings will likely offer significant improvements in performance and reliability across a myriad of applications.

Conclusion

In reviewing the essential role that ball bearings play in industrial machinery, it becomes clear that these components significantly contribute to efficiency, reliability, and performance in various applications. Ball bearings reduce friction between moving parts, thereby enhancing operational smoothness and minimizing wear over time, which is crucial in high-performance machines. The diverse types of ball bearings, such as deep groove, angular contact, and thrust bearings, serve different purposes that cater to the specific requirements of various industries.

The importance of selecting the right type of ball bearing cannot be overstated, as it directly affects the machinery’s overall productivity and longevity. Factors such as load capacity, speed, and environmental conditions must be considered to optimize functionality. Furthermore, advances in technology continue to evolve the design and materials of ball bearings, making it possible to achieve higher performance levels with enhanced durability.

For those interested in delving deeper into the world of ball bearings, there exists a wealth of resources available. Exploring product catalogs, technological innovations, and industry guidelines can provide valuable insights into the latest trends and best practices for selection and maintenance. Additionally, staying informed about advancements in bearing technology can significantly benefit engineers and operators looking to optimize their machinery.

In conclusion, a comprehensive understanding of ball bearings is vital for anyone involved in the industrial sector. As these components remain foundational to machine performance, further exploration of products, technologies, and resources will undoubtedly enhance your knowledge and application of ball bearings.

Types of Ball Bearings

Types of Ball Bearings Table

| Type | Features | Typical Applications | Product Page |

|---|---|---|---|

| Ball Bearing | Supports radial and axial loads, high speed, low maintenance | Electric motors, automotive components, general machinery | View Product |

| Flange Bearing | Mounting flange for easy installation, supports radial loads | Conveyors, motors, industrial machinery | View Product |

| Angular Contact | Handles combined loads, supports axial load in one direction, high-speed capability | High-speed spindles, gearboxes, pumps | View Product |

| Double Row Angular Contact | Supports higher axial and radial loads than single row, stable at high speeds | Machine tool spindles, heavy machinery, gearboxes | View Product |

| Insert Bearing | Pre-assembled with housing, easy to mount, accommodates shaft misalignment | Conveyor systems, agriculture machinery, HVAC systems | View Product |

| Self-aligning Bearing | Two rows of balls, accommodates misalignment, reduces stress on shaft | Electric motors, woodworking machines, conveyors | View Product |

| Thrust Bearing | Supports axial loads only, can handle high axial forces, low radial load | Automotive gearboxes, vertical shafts, turntables | View Product |

| Spherical Plain Bearing | Accommodates oscillating or tilting motion, handles heavy radial loads | Construction equipment, hydraulics, industrial machinery | View Product |